Claire Jackson

Claire Jackson is the Education Director for Galliford Try. She works with our regional teams to ensure that we remain one of the leading contractors in this sector in the UK.

Back in 2012 at Galliford Try we began a journey to engineer a new approach to constructing schools in response to the then Coalition Government’s James Review. The drivers at the time were to find solutions to providing education buildings that reduced capital costs and programme periods.

While some contractors responded by producing an off-the-shelf template design, Galliford Try worked with educators and architects to research and develop a set of principles that would integrate standardisation and repeatability, but would be customer-focused and education led.

We believe that our approach has stood the test of time and this year we are celebrating 10 years of Optimum Schools, the guiding principles of the platform are even more relevant today that they were in 2012.

Our principles were created with the flexibility needed to cope with the wide range of variable requirements relating to site conditions, educational priorities and specialist facilities.

This flexibility has borne fruit over the decade allowing us to meet the challenges of building new schools on constrained new sites, constructing replacement blocks within existing school campuses and working with a multitude of Local Authorities and Multi-Academy Trusts to match their educational delivery models including providing Special Needs Schools.

Our Optimum Schools approach involves 10 key principles. These include among other criteria, creating sustainable buildings, applying a fabric first approach and utilising natural daylighting and ventilation strategies. All of these principles are the bedrock of achieving a lower carbon future, and have allowed us to develop our ideas into the Optimum School Zero concept, which meets the Department for Education’s Net Zero Carbon in Operation targets.

Fabric first is now a default position for all projects to ensure we maximise building efficiency and minimise carbon impact. The optimum orientation of key spaces allows us to make the most of solar gain in key spaces resulting in less energy usage. We also create optimum learning environments through the use of natural cross-ventilation to ensure the best air quality and thermal comfort for occupiers.

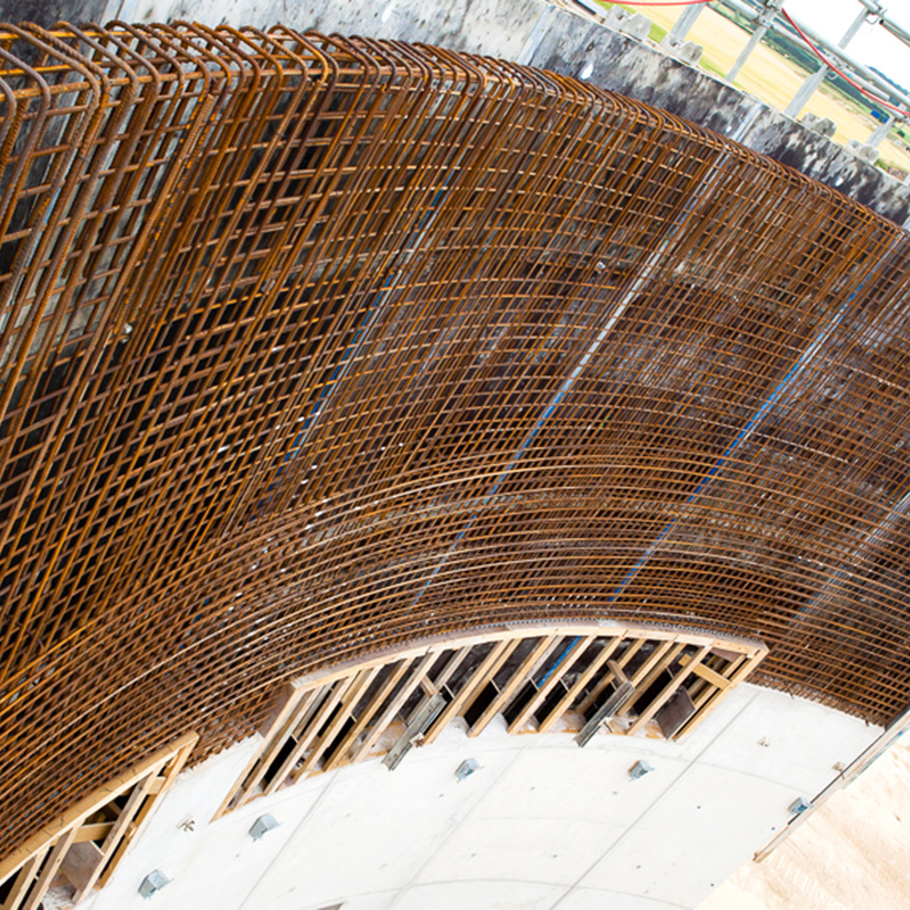

Our Optimum Schools principles have always embraced modern methods of construction (MMC) and offsite manufacture.

From the publication of ‘Modernise or Die’ in 2016 to the government presumption in favour of offsite construction from 2019, MMC has become a part of the mainstream over the last 10 years. Optimum Schools’ repeatable design principles lend themselves to offsite manufacturing methods by incorporating standardised components but with the flexibility to use differing materials. We have been able to deliver schools manufactured and assembled from pre-cast concrete panels and also structurally insulated timber panels (SIPS). By using component-based standardisation principles, rather than a volumetric solution, we are able to apply offsite methods yet still incorporate standard elements in schools even where a more bespoke design has been used.

To ensure maximum efficiencies from our commitment to component-based standardisation we invested in the development of our Education Design Portal, a BIM-based platform which houses our standardised designs and components, and supports repeatability based on common platforms with flexible building forms and construction materials.

We have seen this approach included as a strand within the Government’s new Construction Playbook. ‘Harmonise, digitise, and rationalise demand’ illustrates the benefits and impacts of using standardised components, including efficiencies on site increasing productivity, improved quality, and reducing waste through the implementation of MMC.

Collaborating fully with our supply chain partners has always been central to our ways of working and developing solutions with a fully integrated design team is a key part of our approach which led to a Supply Chain Excellence Award from Construction News in 2014.

This alignment with our supply chain has led us to collaborate in the development of new products to meet changing specifications and piloting and testing products to achieve lower energy consumption overall.

Undoubtedly the future for Optimum Schools and construction within the education sector is going to be based on the drive to reduce carbon, adopt ever-greater digitalisation, and fully embrace MMC to maintain the momentum of modernisation.

The flexibility and forward-thinking nature of Optimum Schools gives us a fantastic platform to be one of the leaders in the industry, achieving those targets, and we look forward to developing our principles to even greater heights over the next 10 years."